|

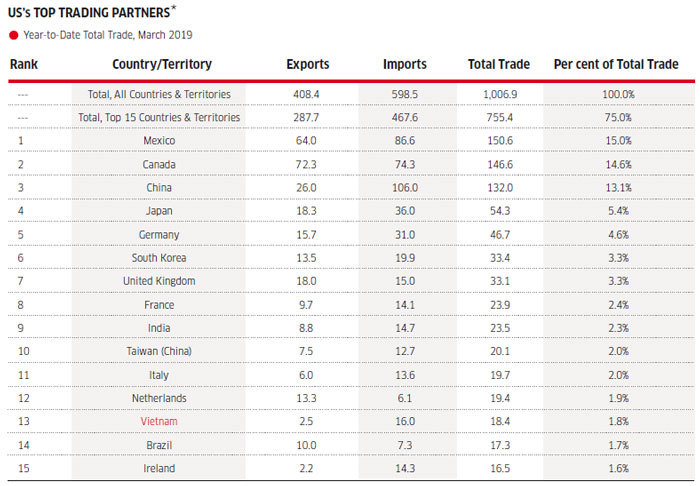

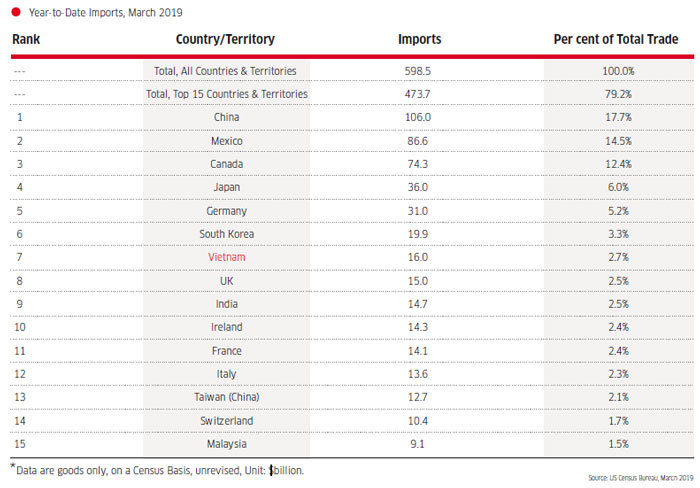

US President Donald Trump tweeted in early May that “Many tariffed companies will be leaving China for Vietnam and other such countries in Asia …” and on the same day raised tariffs on $200 billion worth of Chinese goods from 10 per cent to 20 per cent.

The President’s threats to deepen US-China trade tensions with further tariffs could accelerate the inflow of manufacturing investment into Vietnam and other countries.

Relocations boom

As Legal Manager at Yingke Vietnam, a subsidiary of Yingke Global, a China-based consulting group, Mr. Tony Hieu has been fielding more questions and interest from China-based manufacturers about relocating to Vietnam since last year.

His company has helped many take steps to analyze financial, personnel, and management matters before deciding to invest in the country.

In May, it signed a deal with a China-based textiles manufacturer to relocate its manufacturing factory to an industrial park in Vietnam’s north.

Earlier, a China-based stationery manufacturer quickly made a decision to expand in Vietnam with a new factory due to the rising tariffs.

The company had previously adopted a “wait and see” attitude when the US and China put trade tensions on hold last May.

“Some companies need a reason to make the decision to move, and rising tariffs is such a reason,” he said.

The strong possibility of further tariff increases has made many international groups in China consider relocating production facilities elsewhere, including to Vietnam.

A representative from footwear maker Brooks Running, a subsidiary of Berkshire Hathaway, told VET that the decision to move a major part of its manufacturing operations from China to Vietnam came after President Trump threatened to increase tariffs on shoes from 20 per cent to 45 per cent.

Vietnam emerged as the preferred destination for the company and it is expected to move here by the end of this year. Some 8,000 jobs will come with it.

Meanwhile, the US-based Hasbro, the world’s leading toymaker, plans to reduce its production capacity in China to 60 per cent by 2020, compared to 69 per cent in 2018 and 86 per cent in 2012. The company may resettle some of its production facilities to Vietnam, the US, Mexico, and India.

“For now, China + 1 strategies are centered on Vietnam, Indonesia, and the Philippines,” according to a China Briefing produced in May by professional services provider Dezan Shira and Associates. There are many reasons why Vietnam is emerging as the preferred destination for Foxconn, Samsung, and LG, the Briefing added.

Why Vietnam?

|

Some China-based manufacturers are already well on their way to moving to Vietnam. Multinational Chinese tech company Lenovo plans to build a production facility in the northern province of Bac Giang, manufacturing $3 billion worth of computer parts for export to the US.

Bac Giang authorities received a request from the company in February to introduce it to a suitable industrial park, and it is currently looking at investment procedures and related policies in the province.

Taiwanese iPhone assembler Foxconn, meanwhile, acquired rights to use a property in Bac Giang in late January and plans to expand production to northern Quang Ninh province.

China’s GoerTek, which assembles wireless earphones for Apple, has notified suppliers that it intends to relocate some of its production to Vietnam.

Other foreign companies moved following the introduction last year of tariffs on the first batch of Chinese products. Communications equipment producer Sierra Wireless Inc. has almost completed moving some of its production to Vietnam.

Typical of emerging Asian markets, Vietnam has followed an export-led growth model, combining trade liberalization and FDI promotion to spur exports. It has been active in signing bilateral trade agreements in recent times, with the upcoming Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and the EU-Vietnam Free Trade Agreement (EVFTA) set to make the country’s business environment more competitive.

|

Standards in product quality and employee rights in these agreements will allow the country to become a manufacturing hub and expand as an export base. Lower labor costs in Vietnam are also a factor in manufacturers moving their supply chains away from China.

Many factories in Vietnam are owned by companies from China, Taiwan (China), and South Korea. This makes transitioning out of China into Vietnam smoother, with easy transfer of existing checklists, specifications, or other product information, the Dezan Shira and Associates Briefing noted. Vietnam’s location close to regional shipping routes allows manufacturers entering the country to focus on exports. It also has a stable government, which has invested in industrial zones, and their number is expected to increase as foreign investment pours in.

With such advantages, Vietnam is considered the least-impacted country in ASEAN if the US imposes a 25 per cent tariff on Chinese imports, according to a report on US-China trade tensions conducted in May by the MB Securities JSC.

The country is able to replace part of China’s exports to the US, such as computers, telephones, garments, sports equipment, machinery, and automobile parts.

Local economists said that Vietnam needs to improve the quality of its workforce and infrastructure to fully benefit from becoming a China + 1 destination. Some China-based companies are trying to find suitable industrial parks in Vietnam’s north with good infrastructure, according to Mr. Hieu, and others will do likewise in the time to come. VN Economic Times

Tech key to position Vietnam as a manufacturing leader

Vietnamese firms should hasten technological development to position the country as a global manufacturing centre, Swedish experts said at a seminar on Tuesday.

VN government leader requests steps to develop automobile manufacturing

Prime Minister Nguyen Xuan Phuc requested that ministries, sectors and localities adjust their policies to speed the development of the automobile and support industries.

New usages of MOF material in healthcare, industrial manufacturing

After graduating from the HCMC-based Vietnam University of Science Nguyen Thi Kieu Phuong confidently pursued synthetic chemistry, focusing strongly on metal-organic frameworks (MOFs).

Vietnam is in the sights of many foreign manufacturers keen to move production away from China as US tariffs begin to rise.

Vietnam is in the sights of many foreign manufacturers keen to move production away from China as US tariffs begin to rise.