|

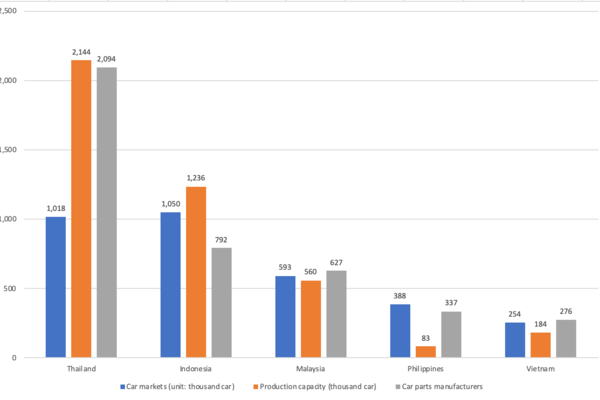

| Vietnam's automobile industry compared to regional peers in 2018. Data: Marklines. Graphic: Nguyen Tung. |

With an automobile industry that only got its proper start in the 2000s, 20 or 30 years after Thailand or Indonesia, Vietnam would need breakthrough policies to close gaps with regional peers, according to Nguyen Trung Hieu, head of the Policy Department under Vietnam Automobile Manufacturers’ Association (VAMA).

“Every country has its own incentive system, so the absence of special treatment would not help Vietnam’s cars to compete with imported ones,” Hieu said at a conference held by the Central Institute for Economic Management (CIEM) on October 22.

To put things in perspective, Hieu mentioned Thailand, a country with a population of 60 million, sold over 1 million cars domestically in 2018 and exported another 1 million, while Vietnam with a market of 100 million saw only 254,000 cars sold in the same period, of which 70,000 cars were imported.

“Vietnam’s market size is forecast to reach Thailand’s current level of 1 million cars by 2030, so the target of catching up the neighboring country is challenging,” Hieu continued.

More importantly, the localization rates of Thailand and Indonesia in their respective automobile industries are 90% for less-than-nine seat cars, significantly higher than Vietnam’s nearly 20%.

Vietnam only has 276 enterprises taking part in the global value chain of car parts, of which the majority are foreign invested companies, compared to Thailand with 2,094 and Indonesia with 792.

This was due to the fact that the supporting industries in Vietnam are only capable of manufacturing low-added value auto parts requiring basic skills and intensive in labor, such as car seats or auto wire harness, while other sophisticated items such as electronic and plastic parts, car chassis, engines, among others, are subject to import.

According to Hieu, the lack of development of the auto parts manufacturing sector is due to the small size of the market, low production skills, poor corporate governance capacity and under-developed basic materials sector.

“Factors such as small market size and low localization rate have made production cost of locally-made cars 10 – 20% more expensive than imported ones,” Hieu asserted.

Moreover, domestically produced auto parts are also facing fierce competition from imported products from ASEAN, which are enjoying zero import tariff under the effect of the ASEAN Trade in Goods Agreement (ATIGA).

Hieu stressed the difference in costs could be partially offset by efforts from enterprises, but it is the government’s policies that play a key role in ensuring greater localization rate in car manufacturing process through incentive and tax policies, as well as to maintain stable growth rate of the domestic car market over a long-term period.

Echoing Hieu’s view, Nguyen Thi Hai Binh, expert at the National Institute for Finance under the Ministry of Finance (MoF), said more policies are needed to boost the development of automobile industries.

Without the presence of strong policies, Vietnam faces the risk of losing the majority share of domestic car markets to foreign players, Binh said.

“Tax incentive polices, therefore, should not only apply for investors but also for customers,” Binh stated.

Binh suggested modification is required for excise tax, including tax exemption for auto parts made domestically. Moreover, other laws, including the land law and credit policies for enterprises are also important to encourage the establishment of auto manufacturing parks.

Vice President of Vietnam Association of Supporting Industries (VASI) Truong Thi Chi Binh said credit preferential policies are essential for greater competitiveness of companies operating in supporting industries.

“The government serving as a focal point supporting enterprises in capital and technologies would help ensure enterprises’ sustainable development,” Binh said.

The MoF is currently reviewing a draft decree in replacement of Decree No.125/2017/ND-CP on export duty schedule, preferential import duty schedule and lists of commodities and their flat tax rates, compound tax rates and outside tariffs quota rates, aiming to increase the localization rate and enhance the competitiveness of Vietnam’s automobile industry.

Local auto manufacturers previously voiced concern over the insufficient support from Decree No.125 for the automobile industry, as it failed to create considerable advantages for domestic cars over imported ones from other ASEAN countries.

Meanwhile, Prime Minister Nguyen Xuan Phuc is instructing government agencies to review the concept of the industry of car assembly to be high-tech manufacturing and thus they would enjoy greater incentives.

With more incentives in place and growing domestic market, prices of locally assembled cars could fall 20 – 30% in the coming time, in turn enhancing its competitiveness against imported ones. Hanoitimes

Nguyen Tung

Automobile sales in Vietnam can set new record in 2019

Vietnam's automobile market is expected to set a new sales record this year with sales of the Vietnam Automobile Manufacturer Association (VAMA) members and TC Motors averaging nearly 32,000 cars each month in January-September.

Vietnam to spend $4.3 billion to develop automobile industry

Experts think the plan to spend $4.3 billion to develop the automobile industry will be in vain.

Without the presence of strong policies, Vietnam faces the risk of losing the majority share of domestic car markets to foreign players, said an expert.

Without the presence of strong policies, Vietnam faces the risk of losing the majority share of domestic car markets to foreign players, said an expert.