When he was a child, Long saw his grandmother preparing ingredients to make mooncakes for the eighth lunar month, and was happy helping her. When he grew up, he did not become a professional baker, but studied at university and went to work for a company after graduation.

However, making mooncakes in a profession handed down from generation to generation in his family, he has deep understanding about the cakes. He noted that nowadays, hand-made mooncakes are no longer available in the market. People now mostly consume cakes made by large workshops in an industrial way.

Therefore, he decided to develop a mooncake brand of his own. The cakes are 100 percent handmade with the best materials.

Long’s cakes quickly became well known and favored. However, Long still was not satisfied with his initial achievements. Two years ago, he saw an ad piece about gold-inlaid mooncakes sourced from Singapore. However, to his surprise, he could not find any gold sheets or dusts on the crust of the cake.

“My father was a gilding craftsman. Reminded of my father’s career, I came up with the idea of gilding my mooncakes,” Long said.

However, it was not easy to inlay mooncakes with gold. After a period of learning, he realized that the gold used to inlay furnishings must be different from the gold covering food.

In general, gold gilding craftsmen use gold mixed with metal to plate things. The characteristic of this type of gold is low purity and brittleness. When inlaying things with gold, craftsmen have to cover items with a layer of paint, or glue, so that gold sheets stick together. However, the method must not be applied to food.

Long found that 9999 gold, or 24K gold, has high purity of 99.99 percent, and can be ingested by humans.

After finding the suitable type of gold which can be used in food, Long faced another challenge: sticking the gold layer to the surface of the cake without any kinds of additives and glue.

“After much research, I discovered that at a thin 9999 sheet gold can naturally adhere to cake crust. Calculating the appropriate thinness of the sheet gold is my secret,” he said.

However, 9999 gold with such a thinness cannot be made in Vietnam, so he has to import the gold from Germany.

When importing this type of gold, Long can receive the certificate on the purity level which can be used for food.

After importing sheet gold from Germany, Long tried to inlay the gold on the crust of mooncakes. As the gold layer was too thin, it easily tore or crumbled.

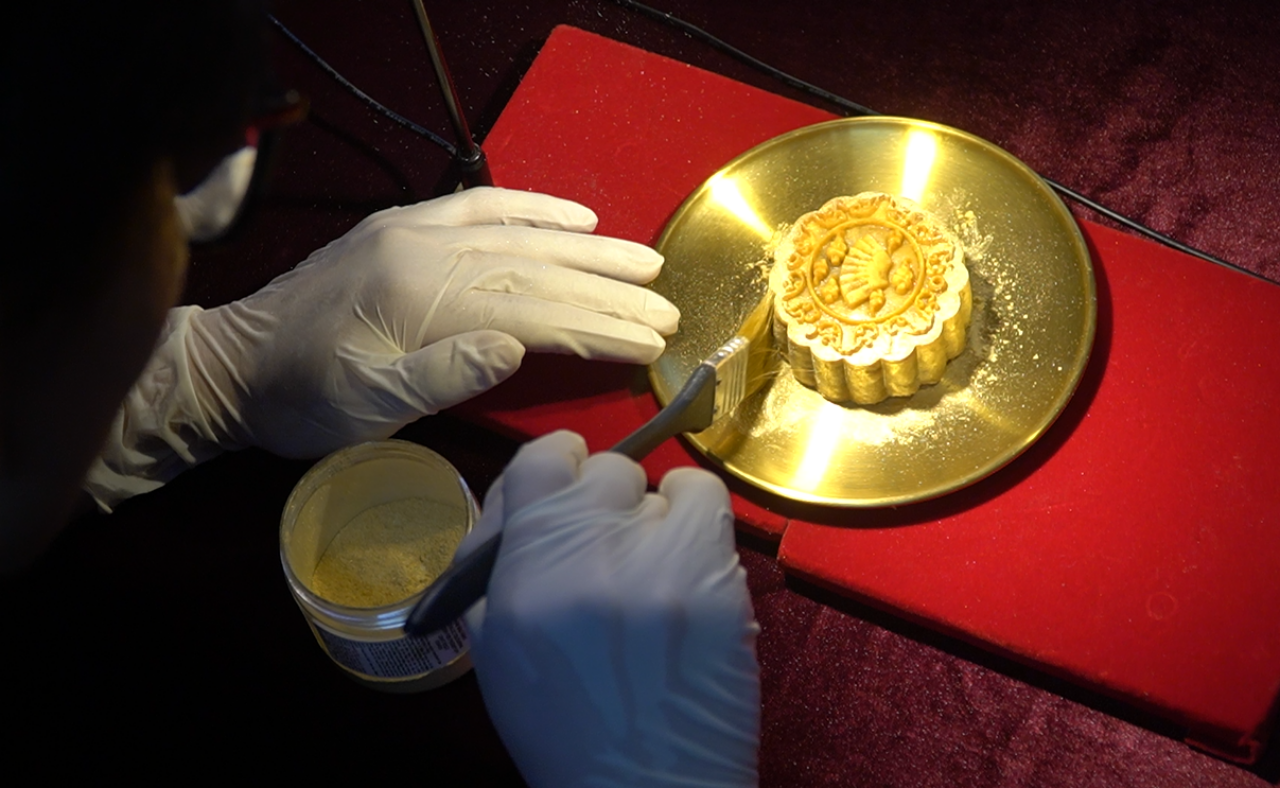

If craftsmen are not skillful enough, gold dust will stick to their hands and the cake. If so, the cake surface will become rough and uneven. Therefore, craftsmen must be meticulous and highly focused when gilding cakes.

According to Long, the process involves placing gold sheets on the surface of the cake so that the sheets automatically adhere to cake, with no additives needed.

The process is successful if the gold sheet layer doesn’t wrinkle, tear or break.

“Before gilding the cake, I cover the sides of the cake with a layer of gold powder. This gold powder is also made of 9999 gold and imported from Germany,” he said.

“All my cakes have production registration certificates and the gold is certified as meeting standards, and can be used in the food industry,” he said.

The speciality of gold-inlaid cake is not only the gold cover, but also the stuffing - abalone, shark fin, or bird's nest.

One gold-inlaid mooncake made by Long sells for more than VND1 million.

“In addition to wealthy customers, we also welcome and produce mooncakes for ordinary people. Many customers buy my products for their relatives as a gift on the occasion of full-moon festival,” he said.

Ha Nguyen