A group of South Korean scientists has achieved a major milestone in battery technology by developing a lithium metal battery without an anode, boasting a volumetric energy density of 1,270 Wh/L - almost twice that of current lithium-ion batteries used in electric vehicles.

The breakthrough, announced by researchers from POSTECH, KAIST, and Gyeongsang National University, could significantly extend the driving range of electric cars.

According to the research team led by Professor Soojin Park and Dr. Dong-Yeob Han of POSTECH, the prototype achieved a volumetric energy density of 1,270 Wh/L, compared with about 650 Wh/L in today’s lithium-ion batteries.

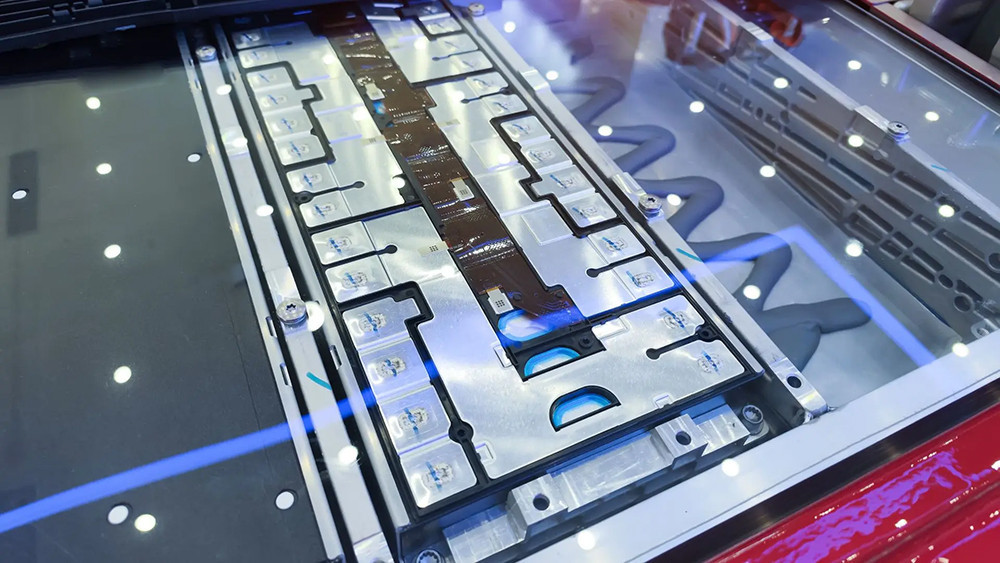

The innovation lies in the anode-free architecture of the lithium metal cell. In this design, the traditional graphite anode is completely removed. Instead, lithium ions from the cathode deposit directly onto a copper current collector during charging.

By eliminating the anode, engineers freed up internal space inside the battery, allowing more active material to be packed into the same volume - essentially, “storing more fuel in the same tank.”

However, anode-free lithium metal batteries have long faced critical challenges, particularly uneven lithium deposition during charging, which can form sharp dendrites capable of piercing the internal separator, causing short circuits and safety hazards.

Additionally, the lithium surface tends to degrade after multiple charge-discharge cycles, reducing efficiency and lifespan - key factors that have prevented commercial viability.

To overcome these obstacles, the researchers introduced a dual-solution approach: a reversible storage framework combined with a specially designed electrolyte.

The storage framework consists of a polymer structure embedded with uniformly distributed silver nanoparticles, guiding lithium to deposit evenly and preventing dendrite formation.

Meanwhile, the custom electrolyte promotes the formation of a stable surface layer of Li₂O and Li₃N on the lithium metal, enhancing ion transport and protecting the electrode throughout repeated use.

With these improvements, the battery demonstrated outstanding performance under demanding conditions. At a capacity of 4.6 mAh/cm² and a current density of 2.3 mA/cm², it maintained 81.9% of its original capacity after 100 cycles, with an average Coulombic efficiency of 99.6%.

Even under low-electrolyte and low-stack-pressure conditions, the cell remained stable, highlighting its potential for lightweight, simplified, and scalable production - a key step toward commercialization.

Professor Park emphasized that the research marks a significant advance in addressing both the performance and durability issues of anode-free lithium metal batteries. Moreover, the use of commercially available electrolyte solvents makes the technology closer to real-world application.

The study has been published in Advanced Materials and has been hailed as one of the most promising breakthroughs in electric vehicle battery technology in recent years.

Duy Anh