Google has tapped mainland-based supplier Goertek to produce its Pixel smartwatches in Vietnam, moving away from its traditional Taiwanese assemblers, Nikkei Asia reported. Goertek is expected to start production of Google’s smartwatches in 2025.

“Partnering with Goertek in consumer electronics manufacturing is purely a business consideration,” an anonymous source stated. “They have manufacturing facilities outside China, guaranteed quality, good service attitude, and competitive prices.”

Simultaneously, BYD has entered the fray, bidding to produce Pixel smartphones in Southeast Asia, a region traditionally dominated by Taiwanese companies. Currently, all Pixel phone orders are with traditional assembly firms, but BYD has demonstrated its capabilities by producing iPads for Apple.

The ambitions of Goertek and BYD highlight the increasing competition in the technology supply chain.

“We are feeling the heat. Currently, our direct competitors are BYD, Goertek, and Luxshare,” said a representative of New Kinpo (Taiwan-China), which has been manufacturing in Thailand for over three decades.

Southeast Asia has emerged as a manufacturing powerhouse, partly due to escalating tensions between Washington and Beijing. Its proximity to China and low labor costs make countries like Vietnam and Thailand attractive for diversifying supply chains.

Data analysis by Nikkei Asia shows that Chinese tech suppliers are among the most active in building factories outside the mainland. For instance, 37% of Apple’s 35 suppliers in Vietnam are Chinese companies.

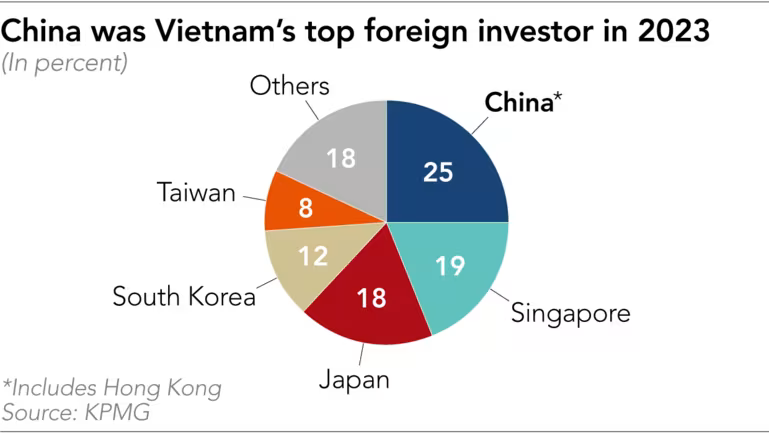

China is a major investor in Vietnam

TCL Technology, one of China’s leading TV makers, has been expanding its capacity in Vietnam since February 2019, aligning with Beijing’s “Belt and Road Initiative” to build infrastructure abroad.

Political tensions are not the only factor pushing Chinese suppliers abroad. The mainland economic downturn has also prompted many companies to explore international opportunities, according to Acter CEO Lai Ming-Kuen. Acter, a Taiwanese manufacturer of manufacturing facilities for various electronics sectors, entered Vietnam in 2009 and has recently invested in Malaysia and Thailand.

“Chinese companies not only offer lower prices to win projects but also have good diplomatic relations with local governments, providing access to numerous business opportunities,” said Lai.

Vincent Chang, regional managing director at Advantech, the world’s largest maker of industrial computers, noted that the “red supply chain” of Chinese suppliers is no longer associated with low prices and low quality.

“Their quality has improved significantly,” said Chang. “They are no longer second-rate suppliers.”

For non-Chinese suppliers, this shift creates unprecedented competition for workers, land, and orders. Printed circuit boards (PCBs) illustrate this competition. According to the Taiwan Printed Circuit Board Association, nearly 55 PCB makers and their suppliers announced plans to invest in Thailand from 2023 to April this year, with 33 being Chinese. At least 13 projects have begun construction in this country.

Brian Chen, a partner at KPMG Taiwan and KPMG Vietnam, said Chinese technology suppliers have made significant investments in Southeast Asia over the past two years. Combined investment from mainland China and Hong Kong surpassed that of Singapore in 2023.

“Take Vietnam as an example. Chinese private and state-owned companies are systematically diversifying their capabilities there,” Chen told Nikkei Asia. He noted that some suppliers are moving to central Vietnam due to congestion in the north.

However, expanding local supply chains could have unintended consequences. Kristy Tsun-Tzu Hsu, director of the Taiwan ASEAN Research Center, noted that Chinese suppliers have been actively setting up production bases in Southeast Asia and Mexico, places the US considers friendly. Washington has started paying attention to mainland brands moving production out of China.

TPCA chairman Maurice Lee, also a senior advisor at Unimicron, warned that fierce competition will arise when total production capacity increases due to geopolitical instability but total demand remains stable. “At that point, companies will have to compete for each order by reducing prices.”

The Vinh