In Quang Ngai Province, discarded betel nut sheaths have found new life as bowls, plates, and food containers, thanks to the ingenuity of Nguyen Van Tuyen. His products have not only made their way into international markets but are now used by a premium airline to serve business-class passengers.

Quang Ngai’s untapped resource

Known as the “land of betel palms,” Quang Ngai boasts over 2,000 hectares of betel nut plantations, primarily in the Son Tay and Nghia Hanh districts.

While farmers harvest and sell betel nuts to traders for export, the fallen sheaths are typically discarded or burned as waste, yielding no economic benefit.

Five years ago, Nguyen Van Tuyen, a 41-year-old resident, saw potential in these discarded sheaths. After researching online, he discovered the sustainable use of betel nut sheaths in India, where they are transformed into environmentally friendly products.

Inspired, Tuyen began developing a business that could generate income for local farmers, protect the environment, and create a steady source of revenue for himself.

Building a business from betel nut sheaths

In late 2019, Tuyen set up a production facility in Nghia Hanh, one of the province’s largest betel nut-growing areas. He imported machinery from India, customized it, and began buying betel nut sheaths from local farmers at VND 1,000 (USD 0.04) per sheath.

“At first, people didn’t believe I would pay for something they considered waste. Now, we have suppliers who collect and deliver the sheaths to us,” Tuyen shared.

The production process involves several steps:

Preparation: The sheaths are soaked to soften, cleaned, and air-dried.

Molding: Using heat-press machines, the sheaths are shaped into bowls, plates, trays, and food containers within 40 seconds at temperatures of 80–120°C.

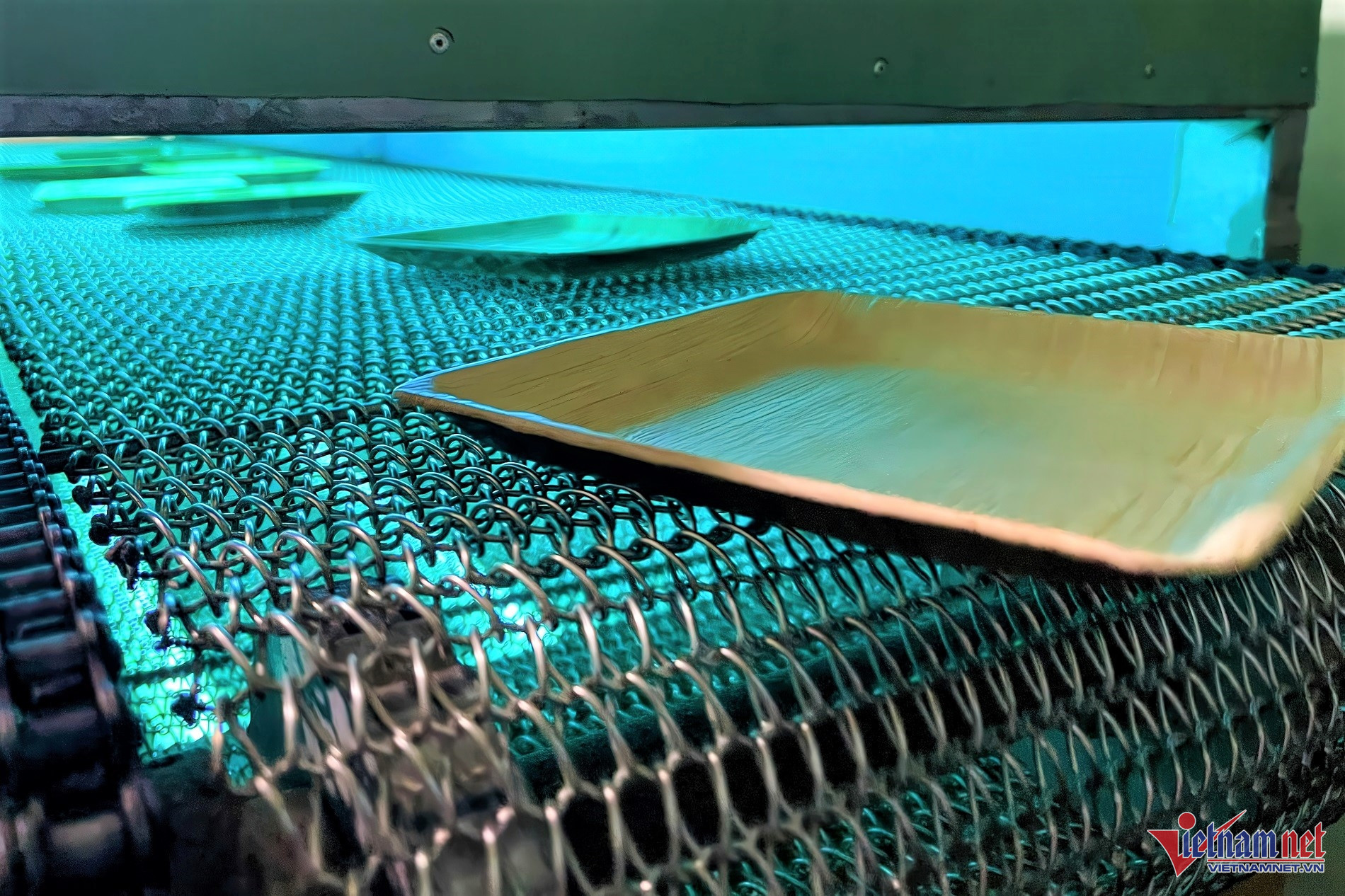

Sterilization: Finished products are sterilized with UV light, ensuring they are hygienic and suitable for holding food, fruits, and spices.

Tuyen’s facility produces over 30 different products, tailored to client specifications.

Each hectare of betel nut trees yields about 12,500 sheaths annually, providing farmers with an additional income of VND 12.5 million (USD 515) per year from this once-discarded resource.

Going global and serving VIPs

In 2020, Tuyen showcased his products at trade fairs, quickly garnering attention and orders. One major milestone was securing a contract with an airline, which now uses his betel nut sheath tableware to serve business-class passengers.

By mid-2021, Tuyen expanded production and now employs 10–12 workers with daily wages of VND 200,000–240,000 (USD 8–10).

Each month, his facility produces approximately 500,000 pieces of tableware, including bowls, plates, and trays.

Priced at just VND 1,000–4,000 (USD 0.04–0.17) per piece, Tuyen’s products are reusable, biodegradable, and highly sought after in international markets.

Today, his tableware is exported to five countries: the Netherlands, the U.S., South Korea, Canada, and Japan. The business generates annual revenue exceeding VND 2 billion (USD 82,000).

Challenges and future plans

Despite his success abroad, Tuyen notes that the domestic market remains reluctant to adopt betel nut sheath products due to their higher cost compared to foam and plastic alternatives.

Recently, his eco-friendly lunch boxes gained attention on social media, prompting Tuyen to focus on this product as a key offering for the domestic market.

“We aim to make these lunch boxes more affordable to reach more consumers,” he said.

Looking ahead, Tuyen plans to explore additional uses for other parts of the betel palm, maximizing its value from root to leaf and further benefiting local farmers.

|

|

Ha Nam