Yen, with 20 years of experience in chip design, in a talk with VietNamNet, introduced himself as someone who understands the advantages and disadvantages of Vietnam’s chip industry.

He worked for a startup in Vietnam and then went abroad to work for one of the world’s largest semiconductor firms, but later returned to Vietnam with the aspiration of building the first Vietnamese owned company which can make money from microchips.

Yen is now building a contingent of Vietnamese engineers who can participate in large projects of international stature, using the most advanced technology – 5nm.

According to Yen, microchip designing firms in Vietnam have many Vietnamese engineers who can participate in the designing process. Vietnam has a qualified workforce which will be expanded when more large corporations continue to invest in Vietnam.

“Vietnam has 5,000 qualified workers who can be present in all stages of the designing process. We also have high numbers of students and reserachers in fields related to engineering and technology,” he said.

“However, Vietnam still has limitations on ownership of designs. If ‘Make in Vietnam’ is understood as possessing designs, microchips and commercialization, we can see that this is the limitation,” he added.

The holes that need to be filled

According to Yen, Vietnam has little foundation for chip manufacturing. Vietnam’s companies have not joined the semiconductor manufacturing ecosystem.

“I think Vietnam is still not ready enough for manufacturing ‘Make in Vietnam’ chips. We just provide a workforce for packaging, testing or support activities in the chip manufacturing process,” he said.

Mentioning the plan to produce engineers for the semiconductor industry, he said that about half a million students in Vietnam apply for universities a year, and if just a small proportion study integrated circuits (IC), Vietnam will have a large workforce for the industry.

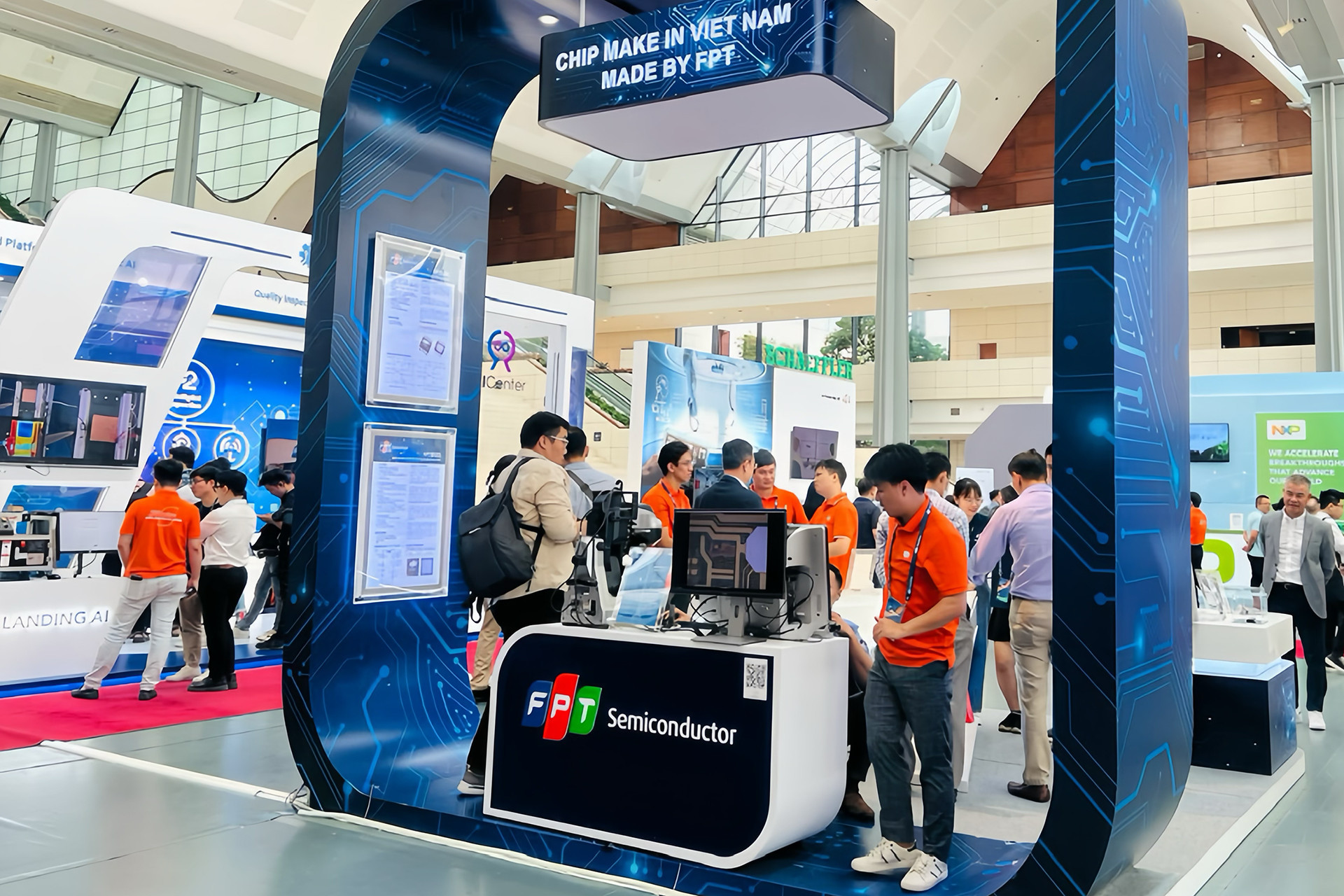

Some Vietnam’s firms have stated recently that they now can manufacture ‘Make in Vietnam’ chips.

The semiconductor industry covers a large sphere, including design; production; packaging; machines and materials for production; and computers supporting production and design.

Microchips tend to have higher integration density. The participation of many parties is needed to create a chip.

“If ‘Make in Vietnam’ means owning or making great contributions to the value chain, Vietnam’s chips need to be ready to compete in terms of quality, price and capability to fulfill orders,” Yen said.

“The ‘holes’ we need to fill is the gap between developed countries and countries that start later in the race. In other words, Vietnam, which started later, needs to find solutions to go faster,” he said.

The ‘chosen’

The news that Vietnam has become a ‘chosen person’ to join the next-generation global chip supply chain has inspired the Vietnamese community.

This conveys a message that Vietnam now has an opportunity which comes once in lifetime to play a greater role in the global chip supply chain.

The geographical position is one of the reasons explaining why Vietnam is a chosen place. From Vietnam, one can see the whole of Asia, which accounts for a large proportion of the global semiconductor market.

The position optimizes logistics costs, plus infrastructure, which is improving rapidly, can bring great advantages to Vietnam in the chain.

Vietnam and the US, which is considered the cradle of technology and startup ecosystems, have upgraded their relationship to comprehensive strategic partnership, which gives a great opportunity.

Over the last 20 years, Vietnamese engineers have proved their working capability. They participate in designing ICs used in automobiles, telecommunications network and billions of household-use electronic appliances used all over the world.

To develop the semiconductor industry, according to Yen, in the immediate time, it is necessary to focus on two categories of policies, including policies to develop human resources, and policies to encourage Vietnamese enterprises’ development.

Binh Minh